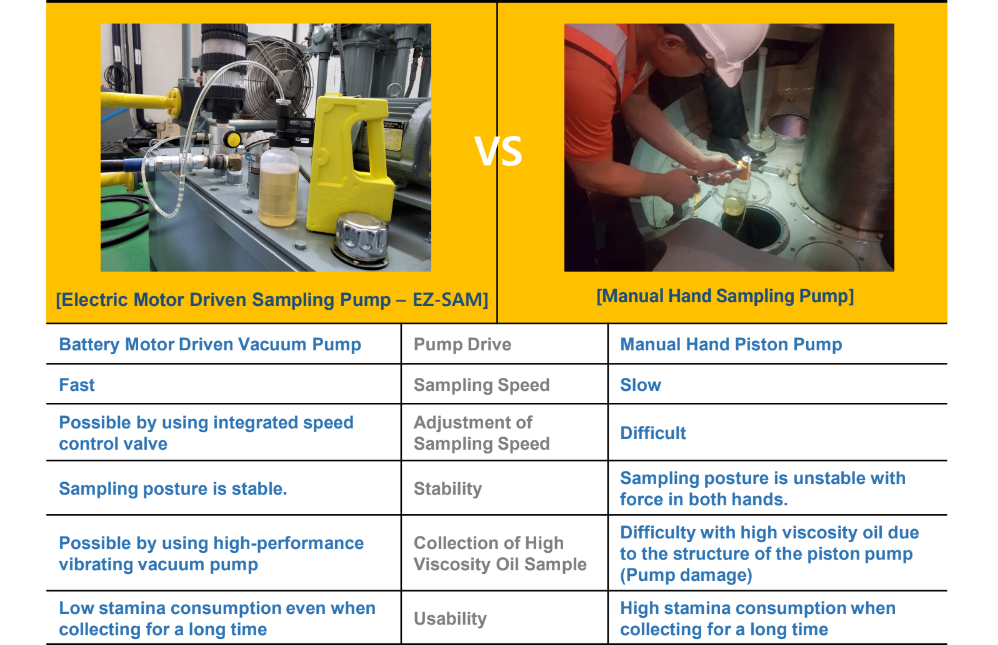

Motorized Sampling Hand Pump

Electric Sampling Pump

Oil sampling is the most important in analysis. In order to increase the reliability of data, uniformity and representativeness should be maintained, and contamination should be protected from airborne. For accurate sampling,

- Sampling Location: location, quantity (representativeness, presistence)

- Sampling Procedure: Standardized so that all team members perform the same at any time

- Sampling Device: It should not disturb the quality of the sample, and it should be easy to use, clean and economical.

- Sampling Bottle: The shape and cleanliness are very important.

- Sampling at least 30 minutes after operation (Enough stirring effect needed)

- In case of sampling when the equipment is stopped, it is carried out immediately after the equipment is stopped.

EZ-SAM

More than 80% of industrial equipment failures are lubrication‐related failures, and most of the causes of lubrication‐related failures are contamination (particles, moisture). It should be possible to monitor and control the causes of these failures through used oil analysis, but most companies ignore the sample bottle for oil analysis that must be used to derive accurate lubricant analysis results and errors caused by using a non‐exclusive sample bottle (capacity, cleanliness) are being overlooked. Expensive oil analysis equipment is important, but for accurate oil analysis, the first is to use a dedicated sample bottle for oil analysis.

Features and composition

-

Complete exclusion of oil confounders

Super Clean level cleanliness (10 pieces/ml)

-

Robust appearance

Prevents distortion when using a vacuum pump

-

Clear sample bottle

Oil color can be visually checked

-

high temperature use

Conventional PET bottles are dented at high temperatures

-

ABS material used

Excellent heat resistance and durability

-

Various options available

Sampling Probes, Sampling Pumps, Sampling Vessels

Key Features

- Convenient and easy sampling compared to manual type Robust. One-handed grip

- Adopted clamping spec for clean vacuum standard sample bottles

- One-touch operating switch

- Sampling speed can be adjusted by an integrated speed control valve

- Samples can be collected without external contamination

- Stable carriage and collection with shoulder strap (Optional)

- Replaceable battery