|

TMR 33-37 RefractometerHigh accuracy refractometer for the soft drinks, fruit juice, sugar, brewing and blending industries…. The TMR 33-37 high accuracy refractometer is ideal for the demanding applications in the soft drinks, fruit juices and sugar refining industries. Also used in the brewing, distilling and blending industries. With close temperature control, the instrument will give repeatability of better than 0.000003RI which makes the TMR 33-37 refractometer the first choice for analysis in other fields such as water purity monitoring. Built in menus guide the user through the analysis set up procedure, ensuring simple, error free operation. Multiple measuring scales including refractive Index (RI), Brix (% sucrose), Temperature Corrected Brix, Zeiss and a user programmable scale. The User Scale is very simple to set up needing just two standard solutions. The units can be defined in any way the operator requires. In the Sugar Purity mode, special built-in software provides automatic calculation of Apparent Sugar Purity when linked to a suitable Optical Activity polarimeter. The calculation allows for the sample clarification process (Wet Lead, Dry Lead or No Lead) and has a simple set up procedure to interface with AA-10, PolAAr or SacchAAr model polarimeters. Maintenance has been virtually eliminated, the instrument has a stabilised LED light source with an expected life of more than 500,000 hours. Sampling is by a built-in peristaltic pump giving excellent precision and reproducibility. The synthetic sapphire prism surface provides reliable, accurate reading even with the most aggressive samples. Additionally, there is a choice of sample cell configurations. The standard simple cell has 1.6mm bore fittings and is designed for non viscous fluids. Liquids containing suspended matter such as natural fruit pulp can be measured using the specially designed ‘Orange juice’ cell. Both cells have a small internal volume (less than 0.5ml) to ensure negligible carry over from previous samples. There is no need to flush the cell between samples. At the end of a sample batch or shift, the cell can be flushed clean using a single button control. This avoids the need to reset the sampling conditions and eliminates errors. For the soft drinks industry, there is an optional ‘Re-sorb’ feature allowing direct readings to be made using carbonated samples and makes the instrument ideal for ‘beside-the-line’ use in a packing hall. In a busy manufacturing environment, the TMR 33-37 has a user defined intelligent stability mode that automatically senses when the sample has come to a constant value. On reaching this point, the instrument reads the sample and outputs the result. This feature avoids lost measuring time and improves efficiency without any compromise to analytical integrity. With initiatives such as GLP, GMP and VAM commonplace in manufacturing and laboratory analysis, traceability of measurements is essential. The TMR 33-37 outputs the date and time of every measurement together with the scale, temperature and measured value. Two RS232 outputs are provided for data collection using a printer and/or PC. There is also a remote input socket to trigger the instrument sampling pump in an automatic on-line set up. Calibration of the instrument can be checked and the set point (zero) adjusted using a few simple keystrokes on the display. Calibration standards are available for routine instrument verification. They are non-toxic and safe for use in a food-processing environment. |

————————————————————————————-

|

CLR 12-70 Contact Lens RefractometerFully automatic, fast, accurate measurement for the contact lens industry…. Designed for fast, accurate measurement of Refractive Index (RI), Water Content or Brix (%Solids), Temperature Corrected Brix complete with 10 user programmable percent water content scales. Uses an advanced version of the procedure recommended in Annex C of BS ISO 10339:1997. Measures clear or coloured iris lenses with equal ease and accuracy. Built in user programmable, water content scales for up to 10 different polymer materials. Working with a leading manufacturer of contact lenses, Index Instruments have developed the CLR 12-70 Fully Automatic Refractometer. The instrument will allow you to measure Refractive Index, Percent Solids and Direct Water Content (using the special user programmable scales), with accuracy and speed. The CLR 12-70 will measure standard clear iris and coloured iris types with equal ease, accuracy and reproducibility. Gone are the problems of slow, inaccurate, manual refractometers. With the CLR 12-70 you can measure an average of 60 samples an hour. The instrument has been designed for simplicity of operation, allowing you to move quality control out of the laboratory and into the production area. Results can be obtained faster and changes in production quality constantly monitored to reduce costs and improve efficiency. The CLR 12-70 has software-controlled keyboard lock, therefore only you, with the correct pass-codes, can change the analysis parameters. Analysis methods used in the instrument have been taken from the recommended procedure in BS ISO 10339:1997 Annex C and BS EN ISO 9914:1997, the British Standards for the Determination of Water Content of Hydrogel Lenses by Refractive Index of Contact Lens Materials. The user simply places the lens or material blank onto the sample holder. On closing the holder, the reading is automatically initiated and the value displayed in the units required – RI, Solids or % H2O. Results can be output to a computer or printer through the built-in RS232 ports. For traceability, date and time is output with every result. A simple identifier can also be added. This can be numeric, alphanumeric (from our Keyboard Accessory) or Barcode scanner. With a digital printer connected you can collect complete analysis details. High Accuracy The instrument has an absolute accuracy of ± 0.0001 RI for typical samples. An operator can achieve good reproducibility (eg ± 0.0005 RI) after simple instruction. The intelligent stability software allows the user to set the level of variation in the reading that is acceptable for their application. Readings are normally carried out at 20ºC, but the CLR 12-70 will handle any temperature up to 70ºC. Accurate temperature control of the synthetic sapphire prism is provided by connecting to a thermocirculator, such as our LTD-6 model. The CLR 12-70 is also fully waterproof to protect it from even the wettest operating environment. |

————————————————————————————-

|

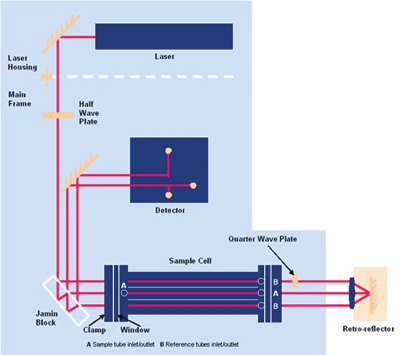

GR1 Gas Laser RefractometerFor the precision measurement of the refractive index of air and gases….. The GR1 Gas Laser Refractometer is a high accuracy optical interferometer which counts the number of fringes that are created by the change in optical path length through the sample cell as the refractive index of the gas within it changes. The GR1 has its own special counting unit (ICF 1/1000) to carry out this exacting task. The unit displays and outputs the results in terms of fringe count, refractive index (RI) or, if the appropriate scaling factors are entered, gas concentration. At the heart of the GR1 lies a special type of self-compensating Jamin interferometer. This ensures that besides being an extremely sensitive instrument, it is also ultra-stable. The GR1 incorporates a patented operating system, developed by the UK National Physical Laboratory (NPL) and manufactured by Index Instruments under licence from the British Technology Group (BTG). The entire system is engineered into a high quality, robust, main frame, designed to withstand the rigours of an industrial environment. It is therefore equally at home in both a research and manufacturing quality control situation. Schematic Layout Applications The GR1 Gas Laser Refractometer has a number of important applications: Firstly, it has a major role in the calibration (and recalibration after routine maintenance) of vaporisers used in the administration of anaesthetic gases during human and veterinary surgery. Many hospitals throughout the world could not perform any surgical procedures were it not for their vaporisers, which are calibrated using the GR1. As such, the GR1 can truly be said to be at the forefront of patient care. Index Instruments were the first commercial company to produce a refractometer of this level of precision and hold the original manufacturing licence granted by BTG. Working in close co-operation with the NPL, Index Instruments took the original concept and turned it into reality as the world’s highest accuracy commercial refractometer. The overall accuracy of anaesthetic gas measurement depends on many factors. These include the accuracy to which the refractive index of the active agent is known and the overall stability of the system. Experience has shown that 1/10th of a fringe, which is easy to measure on the GR1, corresponds to an anaesthetic gas concentration of approximately 0.01%. The ultimate sensitivity of the GR1 is 1/1000th of a fringe (approximately 0.0001%). Other applications for the GR1 are any situation where it is necessary to measure the absolute refractive index of air and other gases throughout industry and research (ref 3,4,5). Gas Tube The standard gas sample tube normally supplied with the GR1 is a trilateral stainless steel type and is an original Index Instruments’ design. It consists of a central tube to take the sample of gas to be measured and a pair of outer reference tubes. These are connected internally. The windows are flat and parallel to interferometric standards. All the tube connections are resistant to anaesthetic agents. The tube length is 316.4mm and the volume is approximately 16ml. The reference tube has a volume of approximately 33ml. Other types of sample tube can be supplied to special order (contact us with details of your precise requirements). Operation To measure the absolute refractive index of the gas, all compartments are evacuated using a pump. Fringes are then counted as sample is slowly re-admitted into the central tube. Changes of the refractive index of the sample can be monitored by sealing the outer reference tubes and recording the movement of interference fringes as sample is pumped through the central tube. Differential measurements between two substances can also be made by flowing a reference gas through the outer tubes and a gas under test through the sample tube. A further option is to seal or evacuate the outer tube, as required, depending on the type of measurement required. |

————————————————————————————-

|

VCH-1 Corneal HydrometerFast and accurate measurement of Corneal Refractive Index during Surgery….. All refractive surgery involving the cornea relies on an accurate measurement of corneal Refractive Index. Many procedures assume the Refractive Index is constant at around 1.376 and its value is unaffected by surgery. In truth, the Refractive Index: You have all the individual details of the eyes you treat but you do not have the individual Refractive Index. This is closely associated with water content of the cornea. All forms of refractive surgery can alter the water content of the cornea – Excimer laser surgery dehydrates the cornea and the VCH-1 will tell you how much water has been lost. The VCH-1 measures Refractive Index in a simple, minimally invasive fashion, with an extra readout of water content. It can be used in all forms of surgery involving either lasers, inlays or grafts. The future of refractive surgery calls for a simple device to measure the Refractive Index of the cornea: i) to further customise and improve treatments. The VCH-1 has been designed and thoroughly tested in clinical trials to fulfil these goals. All types of refractive surgery can affect the water content of the cornea. Changes in the water content, or hydration, can affect corneal biomechanics, influence the post operative refraction and optical quality of the eye. The VCH-1 Corneal Hydrometer estimates the corneal water content by firstly measuring Refractive Index and from this, calculate the water content using an appropriate algorithm. The zone of measurement consists of a round, 4 millimetre wide, illuminated, flat, sterile glass region that is placed directly onto the tissue. The VCH-1 Corneal Hydrometer is a critical angle refractometer that can display and continuously check the light distribution at the region of contact in order to derive a Refractive Index, hence the water content. Once the device detects the measurement, it emits an audible signal informing the surgeon to remove the probe. Both the Refractive Index and water content values are displayed. When performing LASIK, after lifting the flap this hand held device can be placed directly onto the Stromal bed to check the water content of the individual cornea. By repeating the measurement after photoablation the device will indicate the amount of dehydration that occurred in this single case. The VCH-1 Corneal Hydrometer can be used in other corneal procedures such as: LASEK, EpiLASIK, PRK, Intracorneal Inlays and Grafts. If required, the device can also be used to gauge the water content of Hydrogel contact lenses in-situ, for example in therapeutic cases involving Bandage lenses. The device can assist in gaining a better understanding of the effects of surgical procedures in specific cases: i) Stromal Hydration is reduced in older patients and confirmed using the VCH-1 Corneal Hydrometer. |